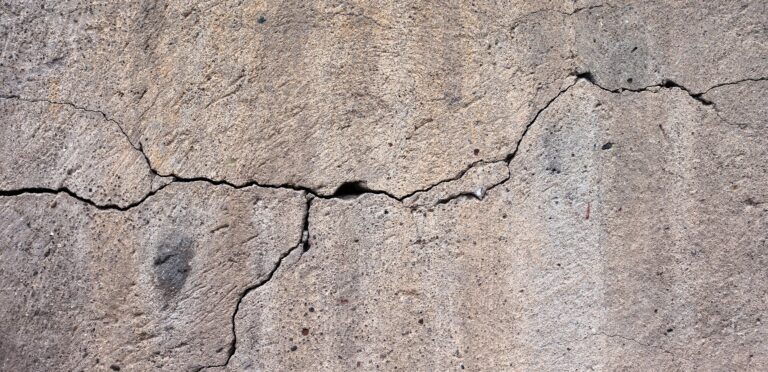

When it comes to concrete crack repair, it is essential to understand and identify the root of the problem before starting. Although many construction projects use concrete for its durability and resistance, it can still be prone to cracks over time. There are several reasons this may occur. To help you identify the problem, we have outlined the five most common types of concrete cracks.

The first two cracks occur when the concrete is in its plastic state. The plastic state is when the concrete is mixed and has not yet set. It is in this initial plastic state that these concrete cracks can occur.

1. Plastic shrinkage cracking

Plastic shrinkage cracking occurs due to water loss at the surface of the concrete before it has set. Immediately after pouring the concrete, it begins to settle. The particles will try to sink toward the bottom as the water rises to the surface of the concrete. This process is known as “bleeding.” If the water at the surface evaporates faster than the rate of bleeding, the concrete will dry and shrink at the surface.

These cracks are most common in horizontal surfaces such as freshly placed floors but can also occur in vertical surfaces. Plastic shrinkage cracks are no bigger than ⅛” wide and are typically 2-4 inches deep. The cracks are usually short but can measure up to a couple of feet long. They run parallel to one another, although they will form randomly throughout the concrete.

2. Plastic settlement cracks

Plastic settlement cracking happens when a restraint obstructs the settling of fresh concrete. In many cases, the restraint is the steel rebar which causes the concrete to settle unevenly. The concrete above the steel rebar settles less than that around or below the bar. Since the steel rebar stays in place and the concrete settles downward, cracks form above the rebar. Similarly, plastic settlement cracks may also occur due to differences in depth where the concrete is poured. In shallower areas, the concrete will settle less than in deeper sections.

Plastic settlement cracks may form at the surface of the concrete or below the surface near the restraint. Additionally, plastic settlement cracks form from the bottom upwards meaning they are not always visible on the surface. Due to how they form, these cracks will have a multiple-crack pattern contrary to plastic shrinkage cracks. For example, cracks often form following the rebar pattern underneath the concrete.

3. Expansion concrete cracks

Another reason concrete may crack is expansion. Expansion cracks form when the concrete expands and pushes against any nearby obstacles. Like many other materials, a concrete slab will expand when exposed to extreme heat. Because concrete does not bend, if there isn’t enough space and the expanding force is too great, cracks will form. To counter this and reduce expansion cracks, adding expansion joints is key when pouring new concrete.

When the concrete slab comes in contact with another structure, expansion joints are put in place. They are typically made of a material that can be compressed such as asphalt, rubber, or timber. These joints allow for the expansion and contraction of concrete during temperature changes by absorbing the pressure, thus reducing concrete cracks.

4. Heaving cracks

Unlike expansion cracks, heaving cracks occur when the temperature drops and the ground freezes. These cracks form due to the freezing and thawing of the soil surrounding the concrete. When the ground freezes, it rises and expands, creating a movement that disturbs the concrete causing cracks to form. As the frozen ground begins to thaw, the concrete will settle back into place although the damage will remain.

In addition to the ground freezing, tree roots can also cause concrete to move and crack. Like soil, roots can push up against concrete, displace it, and ultimately cause it to crack. Unfortunately, it is nearly impossible to prevent this except for removing the root and possibly the tree.

5. Cracks caused by overloading

Overloading a concrete slab with excessive weight for an extended period may also cause cracking. However, this isn’t because the concrete cannot withstand the weight but rather the ground underneath. If a concrete slab has a strength of 5000+ PSI, this means it would take 5000 pounds per square inch to crush it. So while overloading the concrete itself is unlikely, if the ground underneath gives way the concrete can crack. Sometimes this may be due to heavy elements such as trash dumpsters or large vehicles. Additionally, overloading a concrete slab after heavy rains or snowmelt may also result in cracking. Again this is because the ground below the concrete softens and the excess pressure on the concrete causes cracking.

It is important to remember that there are, of course, other reasons that your concrete is cracking. This list is not exhaustive and only gives some small insight into what the issue may be. However, even if the cracks seem minor, the small cracks may lead to more significant problems if left unattended. Regardless of how or why your concrete is cracking, we always recommend contacting a concrete specialist near you.

If you are a specialist in the concrete repair industry, we’d love for you to check out our range of injectors. With their non-return valve, MABI injection packers save you time on the job and increase efficiency.

Read about MABI injection ports for concrete crack repair here.